Prensaestopas de metal a prueba de explosiones (rosca métrica/PG/NPT/G)

Prensaestopas de metal a prueba de explosiones (rosca métrica/PG/NPT/G)

Introducción

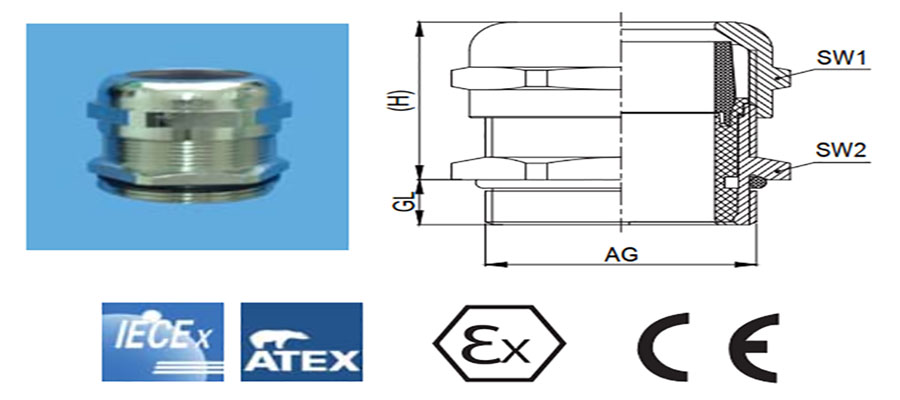

Los prensaestopas se utilizan principalmente para sujetar, fijar y proteger los cables del agua y el polvo. Se aplican ampliamente en campos tales como tableros de control, aparatos, luces, equipos mecánicos, trenes, motores, proyectos, etc.Podemos proporcionarle prensaestopas metálicos fabricados en latón niquelado (Nº de pedido: HSM-EX) y acero inoxidable (Nº de pedido: HSMS-EX).

| Material: | Cuerpo: latón niquelado; junta: poliamida; sellado: caucho modificado |

| Rango de temperatura: | Mín. -40℃,Máximo 100℃,Corto plazo 120℃ |

| Grado de protección: | IP68 (IEC60529) con junta tórica adecuada dentro del rango de sujeción especificado |

| Propiedades: | Resistencia a vibraciones e impactos, según IEC-60077-1999. |

| Aplicaciones: | Construcción de maquinaria, equipos eléctricos, armarios de control eléctrico. |

| Certificaciones: | CE, RoHS, Exe II Gb, IECEx, ATEX. |

Especificación

(Contáctenos para obtener más información si necesita otros tamaños no incluidos en la siguiente lista).

| Prensaestopas de latón niquelado a prueba de explosiones (rosca métrica) | |||||||

| Artículo no. | Hilo | Tamaño del agujero | AG | GL | H | SW1/SW2 | Paquete |

| Dimensión | mm | mm | mm | mm | mm | unidades | |

| HSM-EX-M12 | M12×1,5 | 3~6,5 | 12 | 6 | 19 | 14/14 | 75 |

| HSM-EX-M16-H | M16×1,5 | 3~6,5 | 16 | 7 | 20 | 14/18 | 75 |

| HSM-EX-M16 | M16×1,5 | 4~8 | 16 | 7 | 21 | 17/18 | 75 |

| HSM-EX-M16-D | M16×1,5 | 5~10 | 16 | 7 | 22,5 | 20/20 | 32 |

| HSM-EX-M18 | M18×1,5 | 5~10 | 18 | 7 | 22,5 | 20/20 | 50 |

| HSM-EX-M20-H | M20×1,5 | 5~10 | 20 | 7 | 22,5 | 20/22 | 32 |

| HSM-EX-M20 | M20×1,5 | 6~12 | 20 | 7 | 23,5 | 22/22 | 32 |

| HSM-EX-M20-D | M20×1,5 | 8~14 | 20 | 7 | 23 | 24/24 | 32 |

| HSM-EX-M22 | M22×1,5 | 8~14 | 22 | 7 | 23 | 24/24 | 32 |

| HSM-EX-M24-H | M24×1,5 | 6~12 | 24 | 7 | 23,5 | 24/27 | 18 |

| HSM-EX-M24 | M24×1,5 | 8~14 | 24 | 7 | 23 | 24/27 | 18 |

| HSM-EX-M25-H | M25×1,5 | 8~14 | 25 | 7 | 23 | 24/28 | 18 |

| HSM-EX-M25 | M25×1,5 | 10~16 | 25 | 7 | 24,5 | 28/28 | 18 |

| HSM-EX-M25-D | M25×1,5 | 13~18 | 25 | 7 | 26 | 30/30 | 18 |

| HSM-EX-M27-H | M27×2.0 | 10~16 | 27 | 8 | 24,5 | 28/30 | 18 |

| HSM-EX-M27 | M27×2.0 | 13~18 | 27 | 8 | 26 | 30/30 | 18 |

| HSM-EX-M30-H | M30×2.0 | 10~16 | 30 | 8 | 24,5 | 28/34 | 18 |

| HSM-EX-M30 | M30×2.0 | 13~18 | 30 | 8 | 26 | 30/34 | 18 |

| HSM-EX-M32-H | M32×1,5 | 13~18 | 32 | 8 | 26 | 30/36 | 8 |

| HSM-EX-M32 | M32×1,5 | 15~22 | 32 | 8 | 28 | 36/36 | 18 |

| HSM-EX-M32-D | M32×1,5 | 18~25 | 32 | 8 | 33 | 40/38 | 8 |

| HSM-EX-M33 | M33×2.0 | 18~25 | 33 | 8 | 33 | 40/38 | 8 |

| HSM-EX-M36-H | M36×2.0 | 15~22 | 36 | 8 | 28 | 36/40 | 8 |

| HSM-EX-M36 | M36×2.0 | 18~25 | 36 | 8 | 33 | 40/40 | 8 |

| HSM-EX-M40-H | M40×1,5 | 18~25 | 40 | 9 | 33,5 | 40/45 | 8 |

| HSM-EX-M40 | M40×1,5 | 22~30 | 40 | 9 | 35,5 | 45/45 | 8 |

| HSM-EX-M40-D | M40×1,5 | 22~32 | 40 | 9 | 38,5 | 50/50 | 4 |

| HSM-EX-M42 | M42×2.0 | 22~32 | 42 | 9 | 38,5 | 50/50 | 4 |

| HSM-EX-M48 | M48×2.0 | 22~32 | 48 | 9 | 38,5 | 50/52 | 4 |

| HSM-EX-M50 | M50×1,5 | 30~38 | 50 | 9 | 40 | 58/55 | 4 |

| HSM-EX-M56 | M56×2.0 | 30~38 | 56 | 9 | 40 | 58/60 | 2 |

| HSM-EX-M60 | M60×2.0 | 37~44 | 60 | 10 | 41 | 65/65 | 2 |

| HSM-EX-M63 | M63×1,5 | 37~44 | 63 | 10 | 41 | 65/70 | 2 |

| HSM-EX-M63-D | M63×1,5 | 42~53 | 63 | 10 | 44,5 | 75/75 | 2 |

| HSM-EX-M64 | M64×2.0 | 37~44 | 64 | 10 | 41 | 65/70 | 2 |

| Prensaestopas de latón niquelado a prueba de explosiones (rosca PG) | |||||||

| Artículo no. | Hilo | Tamaño del agujero | AG | GL | H | SW1/SW2 | Paquete |

| Dimensión | mm | mm | mm | mm | mm | unidades | |

| HSM-EX-P07 | PG7 | 3~6,5 | 12.5 | 6 | 19 | 14/14 | 75 |

| HSM-EX-P09-H | PG9 | 3~6,5 | 15.2 | 7 | 20 | 14/17 | 75 |

| HSM-EX-P09 | PG9 | 4~8 | 15.2 | 7 | 21 | 17/17 | 75 |

| HSM-EX-P11 | PG11 | 5~10 | 18.6 | 7 | 22,5 | 20/22 | 75 |

| HSM-EX-P13.5-H | PG13.5 | 5~10 | 20.4 | 7 | 22,5 | 22/22 | 32 |

| HSM-EX-P13.5 | PG13.5 | 6~12 | 20.4 | 7 | 23,5 | 22/22 | 32 |

| HSM-EX-P16-H | PG16 | 6~12 | 22,5 | 7 | 23,5 | 22/24 | 32 |

| HSM-EX-P16 | PG16 | 8~14 | 22,5 | 7 | 23 | 24/24 | 32 |

| HSM-EX-P21-H | PG21 | 10~16 | 28.3 | 7 | 24,5 | 28/30 | 18 |

| HSM-EX-P21 | PG21 | 13~18 | 28.3 | 7 | 26 | 30/30 | 18 |

| HSM-EX-P29-H | PG29 | 15~22 | 37 | 8 | 28 | 36/40 | 8 |

| HSM-EX-P29 | PG29 | 18~25 | 37 | 8 | 33 | 40/40 | 8 |

| HSM-EX-P36 | PG36 | 22~32 | 47 | 9 | 38,5 | 50/50 | 4 |

| HSM-EX-P42 | PG42 | 30~38 | 54 | 9 | 40 | 58/58 | 2 |

| HSM-EX-P48 | PG48 | 37~44 | 59.3 | 10 | 41 | 65/65 | 2 |

| Prensaestopas de latón niquelado antideflagrante (rosca PG: rosca alargada) | |||||||

| Artículo no. | Hilo | Tamaño del agujero | AG | GL | H | SW1/SW2 | Paquete |

| Dimensión | mm | mm | mm | mm | mm | unidades | |

| HSM-EX-P07-L | PG7 | 3~6,5 | 12.5 | 10 | 19 | 14/14 | 50 |

| HSM-EX-P09-HL | PG9 | 3~6,5 | 15.2 | 10 | 20 | 14/17 | 50 |

| HSM-EX-P09-L | PG9 | 4~8 | 15.2 | 10 | 21 | 17/17 | 50 |

| HSM-EX-P11-L | PG11 | 5~10 | 18.6 | 10 | 22,5 | 20/20 | 50 |

| HSM-EX-P13.5-HL | PG13.5 | 5~10 | 20.4 | 10 | 22,5 | 20/22 | 32 |

| HSM-EX-P13.5-L | PG13.5 | 6~12 | 20.4 | 10 | 23,5 | 22/22 | 32 |

| HSM-EX-P16-HL | PG16 | 6~12 | 22,5 | 10 | 23,5 | 22/24 | 32 |

| HSM-EX-P16-L | PG16 | 8~14 | 22,5 | 10 | 23 | 24/24 | 32 |

| HSM-EX-P21-HL | PG21 | 10~16 | 28.3 | 12 | 24,5 | 28/30 | 18 |

| HSM-EX-P21-L | PG21 | 13~18 | 28.3 | 12 | 26 | 30/30 | 18 |

| HSM-EX-P29-HL | PG29 | 15~22 | 37 | 12 | 28 | 36/40 | 8 |

| HSM-EX-P29-L | PG29 | 18~25 | 37 | 12 | 33 | 40/40 | 8 |

| HSM-EX-P36-L | PG36 | 22~32 | 47 | 15 | 38,5 | 50/50 | 2 |

| HSM-EX-P42-L | PG42 | 30~38 | 54 | 15 | 40 | 58/58 | 2 |

| HSM-EX-P48-L | PG48 | 37~44 | 59.3 | 15 | 41 | 65/65 | 2 |

| Prensaestopas de latón niquelado a prueba de explosiones (rosca G) | |||||||

| Artículo no. | Hilo | Tamaño del agujero | AG | GL | H | SW1/SW2 | Paquete |

| Dimensión | mm | mm | mm | mm | mm | unidades | |

| HSM-EX-G3/8 | G3/8″ | 4~8 | 16.66 | 8 | 21 | 17/20 | 32 |

| HSM-EX-G1/2-H | G1/2″ | 5~10 | 20,99 | 8 | 22,5 | 20/24 | 32 |

| HSM-EX-G1/2 | G1/2″ | 6~12 | 20,99 | 8 | 23,5 | 22/24 | 32 |

| HSM-EX-G1/2-D | G1/2″ | 8~14 | 20,99 | 8 | 23,5 | 24/24 | 32 |

| HSM-EX-G3/4-TH | G3/4″ | 6~12 | 26.44 | 8 | 23,5 | 22/30 | 18 |

| HSM-EX-G3/4-H | G3/4″ | 8~14 | 26.44 | 8 | 23,5 | 24/30 | 18 |

| HSM-EX-G3/4 | G3/4″ | 13~18 | 26.44 | 8 | 26 | 30/30 | 18 |

| HSM-EX-G1 | G1″ | 18~25 | 33.24 | 9 | 33 | 40/40 | 8 |

| HSM-EX-G1 1/4 | G1 1/4″ | 22~32 | 41,91 | 10 | 38,5 | 50/50 | 4 |

| HSM-EX-G1 1/2 | G1 1/2″ | 30~38 | 47,8 | 10 | 40 | 58/55 | 2 |

| HSM-EX-G2 | G2″ | 37~44 | 59,61 | 11 | 41 | 65/65 | 2 |

| Prensaestopas de latón niquelado a prueba de explosiones (rosca NPT) | |||||||

| Artículo no. | Hilo | Tamaño del agujero | AG | GL | H | SW1/SW2 | Paquete |

| Dimensión | mm | mm | mm | mm | mm | unidades | |

| HSM-EX-N3/8 | TNP3/8 | 4~8 | 16.65 | 16 | 21 | 17/20 | 32 |

| HSM-EX-N1/2-H | NPT1/2″ | 5~10 | 21,85 | 20 | 22,5 | 20/23 | 32 |

| HSM-EX-N1/2 | NPT1/2″ | 6~12 | 21,85 | 20 | 23,5 | 22/23 | 32 |

| HSM-EX-N1/2-D | NPT1/2″ | 8~14 | 21,85 | 20 | 23,5 | 24/24 | 32 |

| HSM-EX-N3/4-TH | NPT3/4″ | 6~12 | 26.3 | 21 | 23,5 | 22/30 | 18 |

| HSM-EX-N3/4-H | NPT3/4″ | 8~14 | 26.3 | 21 | 23 | 24/30 | 18 |

| HSM-EX-N3/4 | NPT3/4″ | 13~18 | 26.3 | 21 | 26 | 30/30 | 18 |

| HSM-EX-N1 | NPT1″ | 18~25 | 33.15 | 26 | 33 | 40/40 | 8 |

| HSM-EX-N1 1/4 | NPT1 1/4″ | 22~32 | 41,85 | 26 | 38,5 | 50/50 | 4 |

| HSM-EX-N1 1/2 | NPT1 1/2″ | 30~38 | 47,75 | 27 | 40 | 58/55 | 2 |

| HSM-EX-N2 | NPT2″ | 37~44 | 59,55 | 27 | 41 | 65/65 | 2 |